-

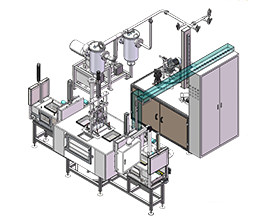

In the area of power transmission and distribution, some products use epoxy resin as the insulation material, such as embedded pole, insulator, contact box, sleeve and so on. Epoxy resin and hardener by vacuum degassing and formulation metering, then casting into the product, form the solid insulation parts after heating. Or adopt the automatic pressure gel clamping process, which develops on the basis of epoxy resin vacuum casting process, is a form of the APG technology. At present, the production of these products adopt APG production process, the conductive terminals and other parts connected by epoxy resin curing, the epoxy resin is no only the main insulation medium, it has outstanding advantages of excellent dimensional stability and high mechanical strength.

-

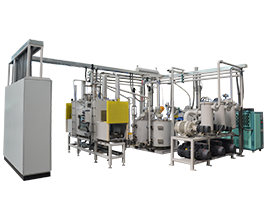

● Small package filler or dust-free ton bag, to prevent dust pollution in the workshop, the filler mixing and heating under vacuum, let the material degassing and dewatering sufficiently.

● Resin, hardener automatically continuous loading, the material will be divided into two non-reactive A/B components, material loading by ratio according to the automatic metering, loading accurate and stable.

● Single-component material mixing and heating under vacuum, adopts the umbrella thin film degassing technology to lift the material through screw to the top, then flow down from the umbrella cover to form a thin film, improving the degassing efficiency.

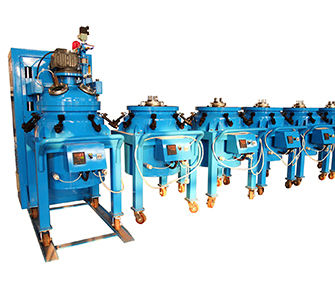

● A/B component is measured and conveying automatically according to the ratio, uses dynamic or static mixing mode to mix the A/B components, then casting the material into the products to heating and moulding.

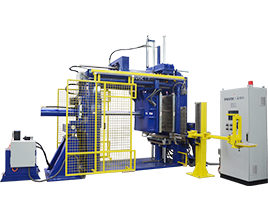

● The formulation system of epoxy resin mixture is highly reactive, which is controlled and guaranteed by reliable equipment and process parameters for gel in a short time.

● The mold temperature of the product is higher than the temperature of the epoxy mixture system, about 80~100 ℃, so that the gel process of the curing reaction starts from the die wall and spreads to the middle epoxy resin mixture.

●In the process of epoxy resin gel curing reaction, keep the pressure of the mixture, pull the epoxy resin mixture system into the moulding chamber under the constant pressure, fill in the voids formed by the volume contraction of the gel process. -

● Environmental protection design, energy saving, reduce emission and labor intensity.

● Material automatic loading, metering, mixing, conveying and injection moulding.

● The powerful control system monitors the equipment status and process flow, records real-time the relevant parameters of the production, and the data can be read anytime.

● Adopt high quality heating rod, high heat conduction efficiency, precise processing of dynamic and static plate, ensure the temperature uniformity of the whole plate.

● The real-time pressure of the hydraulic cylinder can be monitored automatically, when the pressure exceeds the set point, the system will decompression automatically, ensure the constant pressure of the system.

● It can automatically monitor and control the pressure and flow of injection process. It can provide larger feeding pressure, eliminate the bubbles produced by gel contraction and exhaust defects, improve the quality of products.

● Production process formula management, it can arbitrary storage and call the data.

● It can connect to MES system, data management.

insvac@insvac.com